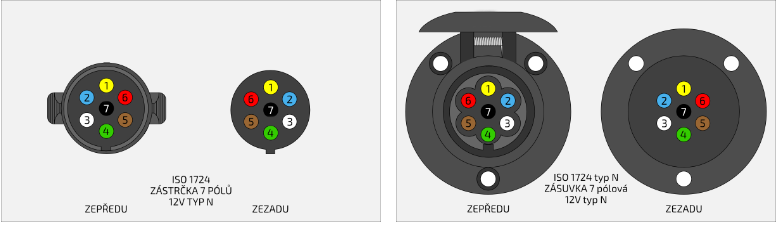

Plug/socket 7 pole 12V - ISO 1724 type N

1 - yellow - left indicator light - turn signal (L)

2 - blue - fog light (54g)

3 - white - carcass, negative pole (31)

4 - green - right indicator light - turn signal (R)

5 - brown - right rear light (58R)

6 - red - brake light - both sides (54)

7 - black - left rear light (58L)

The wire colour connections according to ISO 1724 define the standard for the electrical connection between the towing vehicle and the trailer. This standard, first published in 1980 and last revised in 2003, is designed to provide a uniform framework for these connections. The specification 'Type N' refers to the 'normal' variant, while 'Type S' is defined in ISO 3732 and refers to the 'supplementary' type that carries additional functions, such as continuous current for caravans. ISO 1724 plugs are only suitable for O1 category caravans as 7 pins are sufficient for basic lighting functions without a reversing lamp. If a reversing light is required, either an additional supplementary plug (ISO 3732) or a 13-pin connector (ISO 11446) must be used. The same applies for towing a caravan, as ISO 1724 cannot provide a continuous current.

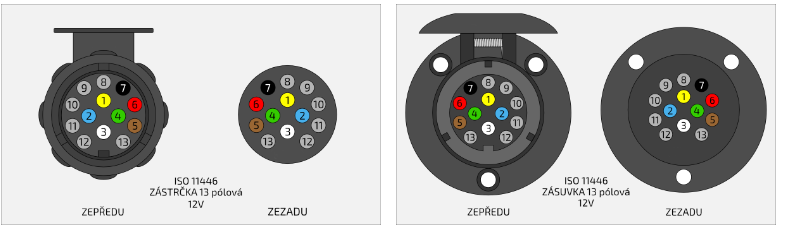

Plug/socket 13 pole 12V - ISO 11446

1 - yellow - indicator light on the left - turn signal

2 - blue - fog light

3 - white - base frame, negative pole for contacts 1 to 8

4 - green - indicator light on the right - turn signal

5 - brown - right rear light (tail light)

6 - red - brake light - both sides

7 - black - left rear light (tail light)

Some vehicle manufacturers prefer different wire colour designations, especially for contacts 8 to 13.

8 - pink - reversing lamp - both sides

9 - orange - permanent power supply, positive pole

10 - grey - power supply, positive pole via switch

11 - white/black - base frame, negative pole for contact 10

12 - reserved for future use

13 - white/red - base frame, negative pole for contact 9

With the increasing requirements for the trailer to vehicle connection, it was necessary to upgrade the original 7-pole connectors. In the late 1980s, Erich Jaeger, together with other key players in the automotive industry, developed a system of 13-pole 12V connectors. The new 13-pole system made it possible to transmit all lighting functions and other electrical functions through a single connector.

For interfacing with older 7-pole systems, reductions are available from both the 7-pole socket to 13-pole plug and from 13-pole socket to 7-pole plug. The reducers always convert only the first 7 poles due to the limitation of the number of poles in a 7-pole socket/plug - the other poles would not be able to be connected. Therefore, most reducers have only 7 pins/holes correctly fitted on the 13-pole side.

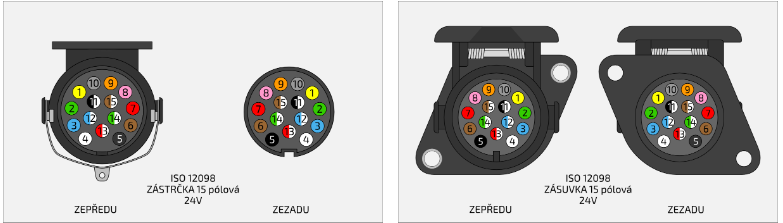

Plug/socket 15 pole 24V - ISO 12098

1 - yellow - left turn signal - turn signal

2 - green - right indicator - turn signal

3 - blue - fog light

4 - white - base, negative pole

5 - black - left rear light (tail light)

6 - brown - right rear light (tail light)

7 - red - brake light - both sides

8 - pink - reversing light - both sides

9 - orange - permanent power supply, positive pole

10 - grey - flywheel brake lock and axle steering

11 - white/black - traction control system

12 - white/blue - axle lifting device

13 - white/red - base frame, negative pole for data wires

14 - white/green - CAN-H data link

15 - white/brown - CAN-L data line

The ISO 12098 standard was designed to replace ISO 1185 and 3731. The 15-pin connector allows the same functions to be transferred between the tow vehicle and trailer as the previous two-pin system, in a single connector. It also includes two data lines (CAN-H and CAN-L) according to ISO 11992-3 for the exchange of information between devices other than braking systems and chassis (these are part of the ABS/EBS system according to ISO 7638-1).

ISO 12098 specifies the dimensional characteristics of 15-pin connectors for the electrical connection of devices other than braking systems and chassis used on towing and towed vehicles with 24 V nominal supply voltage. It includes contact distribution, testing and requirements for the trailer system, and also standardizes the storage socket for storing the disconnected plug and how to adapt between 7 and 15 pin connectors.

_(1)_(1).jpg)